Home

Innovative Power Solutions for Everyone

Inverters & UPS

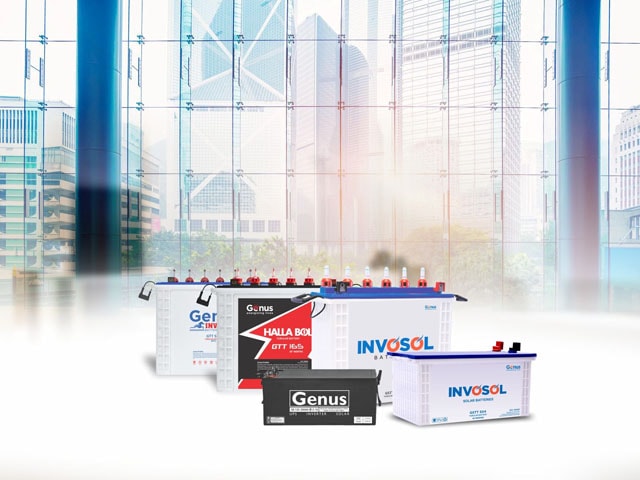

Batteries

Solar Solution

What We Offer

Truly Made In India

Technology Specialists

Power Sector Experts

In House R&D

Customer Testimonials

About Us

Genus Innovation is an integral part of the esteemed Kailash Group, worth USD 400 million. We pride ourselves in designing, developing and manufacturing state-of-the-art power solutions that are driven by innovative technology and design. We also provide OEM services to companies seeking manufacturing expertise in power backup sector.

Our parent company, Genus Power, is the biggest meter-manufacturing company in India and has already installed million of meters throughout India. Chances are the meter outside your home is one manufactured by Genus, go check? We also design, develop and manufacture various eco-friendly solar power products such as Solar Inverters, Solar Panels, Solar Power Conditioning Units, Batteries and more. Certifications like ISO 9001, 14001 & 50001, TUV, BIS, IEC, UL and CMMI Level 3 have cemented our position in the power industry.

Have a Question ?

Blogs

In these unprecedented times, Genus Family urges you to:

1. Wear a mask at all times for your safety and of those around you. Read More

2. Keep your hands and your surroundings clean.

If you need any help, send an email to customer.care@genus.in for immediate response

OK

In these unprecedented times, Genus Family urges you to:

1. Wear a mask at all times for your safety and of those around you. Read More

2. Keep your hands and your surroundings clean.

If you need any help, send an email to customer.care@genus.in for immediate response

OK